Swedish automobile major, Volvo Group, could cut down carbon dioxide emissions by 0.86 million tons per year, thanks to a minor alteration in the supply chain. The company has announced that it will begin procuring green engine castings from the TVS Group’s Brakes India as part of its ongoing sustainability initiatives.

The procurement will see select Volvo engines go green once procurement kicks off later this month. The company says all its engines will soon receive the upgrade.

“It’s just a question of which ones we start with. We’re starting with the bigger ones — the 16-litre and 13-litre engines but progressively it will be for all,” said Kamal Bali, President and MD, Volvo Group India.

“Ultimately, Volvo is going to become a completely net-zero company by 2040, and by 2030, we want 50 percent of our Volvo trucks to be net-zero,” Bali said.

Volvo and Brakes India claim that the intervention will see Volvo cut down carbon dioxide emissions by 0.86 million tons per year. Of this, sustainably produced bearing caps and bearing housings alone will reduce CO2 emissions by 8,500 tons.

What are green castings?

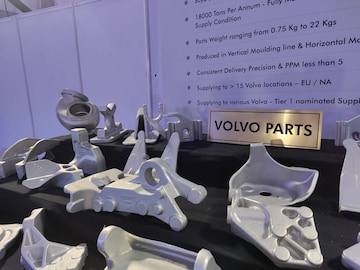

What makes engine castings green is the fact they’re produced using scrap metal, alloys and recyclable material. The sustainable process is also powered by renewable energy sources like solar and wind. Most crucially, it eliminates the use of pig iron, which is usually forged in a coal-powered blast furnace.

According to some estimates, if the automobile industry adopts green castings, carbon dioxide emissions could drop by a whopping 210 million tons per year.

On its part, Brakes India hopes to sell sustainable products to other OEMs too. While it won’t divulge names, the company’s expansion and investment roadmap are indicative of a big order book in the works.

The company’s total capacity stands at 180,000 tons today. It intends to expand this with an investment of Rs 120 to Rs 130 crore over the next year.

“Out of the 180,000 tons, we already produce 145,000 tons in castings,” said Sriram Viji, Managing Director, Brakes India. “We can go further without straining our capacities too much, but I expect that in the next year, we will have to commit to an additional foundry line, which will increase our capacity somewhere in the range of 20,000 to 25,000 tons further.”

Should these plans fructify and more OEMs buy engines made from scrap metal through sustainable processes, there’s no denying it will end up becoming a giant leap for cleaner, greener mobility.

First Published: Jun 24, 2022 3:07 PM IST